- Home

- Manufacturing of Machine Tools

- Single-disk (bottom) grinding machine

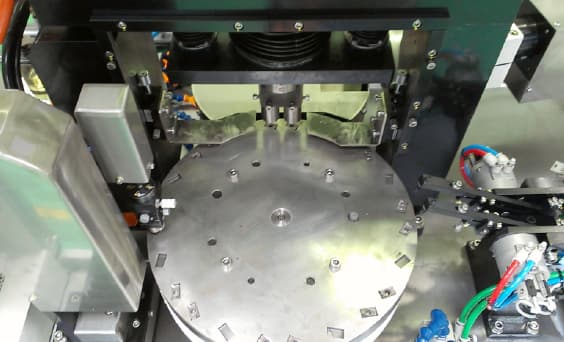

Fully unmanned operation of mass production

even for complex-shaped workpieces

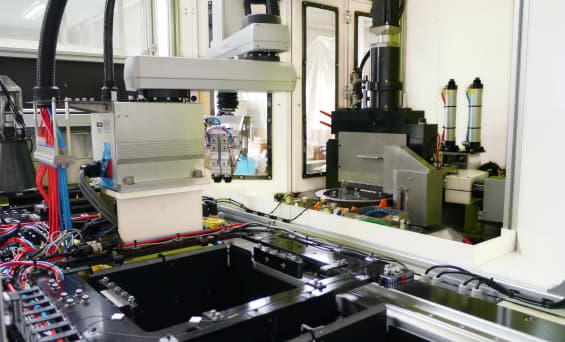

Single-disk (bottom) grinding machine HSDB-250

Features of Machine

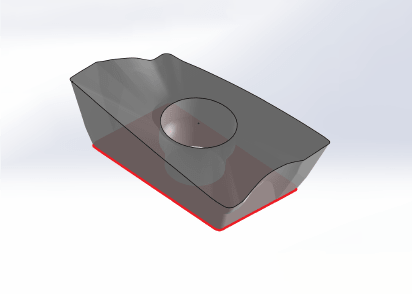

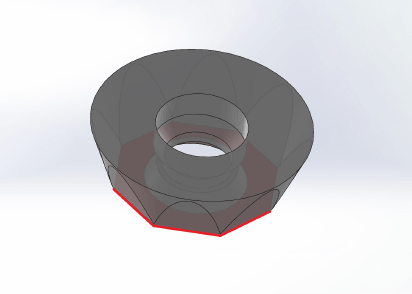

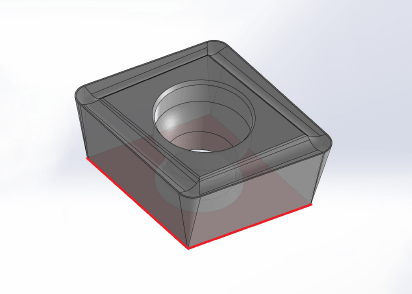

01 Accommodates complex-shaped workpieces

Bottom grinding of cemented carbide inserts for Wavemill, one side grinding of complex-shaped workpieces, etc. which cannot be handled by an ordinary surface grinding machine, can be accommodated.

02 Simultaneous machining of 2 workpieces for higher productivity

Sufficient rigidity provided for the grinding wheel spindle shaft, the rocking shaft and the workpiece presser shaft enables simultaneous machining for 2 workpieces.

03 Automatic transfer of workpieces

The transfer robot and the pallet stacking device enable the fully automatic process of workpieces.

The automatic dressing unit, provided as standard issue, stabilizes machining precision and keeps the grinding wheels in good condition. Also, the automatic thickness measurement system for workpieces provides real-time feedback of measurement results.

The full automation of transfer, machining, measurement and dressing enables fully unmanned mass production.

SPECIFICATIONS

| Applicable work size | Inscribed circle | Φ3.97mm - 16.0mm |

|---|---|---|

| Thickness | t2.38mm - 6.35mm | |

| Grinding unit | Z axis Brush wheel elevation(NC) |

30mm |

| Y axis Wheel oscillation(NC) |

0~10mm | |

| Grinding wheel rpm |

Max. 3000min-1 | |

| Grinding wheel size |

OD 250mm ID 50.8mm W 25mm T 35mm |

|

| Machine size | W1805mm × D1170mm × H2100mm(Excluding Carrier) W2665mm × D1365mm × H2100mm(Including Carrier) |

|

| Power supply | 15KVA(carrier device) | |

| CNC Control system | FANUC 4 axis control simultaneous 2 axis | |

|---|---|---|

| Loading & unloading system | YAMAHA SCARA robot | |

| Work unit | X axis Work holder (NC) |

30mm |

| C axis Carrier jig indexing (NC) |

1 - 360° | |

| Dressing unit/dresser | Dressing wheel rpm |

Max. 1550min-1 |

| Dressing wheel size |

OD 100mm ID 25.4mm T 20mm |

|

| Machine weight | 3500kg(carrier device) | |