- Home

- Contract Manufacturing

Hikari Kikai Seisakusho uses the technology nurtured throughout its long history and the latest equipment to achieve polishing and grinding of difficult shapes with microlevel precision.

-

Sophisticated Machining Technology

Grinding technology accumulated over more than 70 years using the latest equipment

-

Integrated Production for Quality and

Delivery ControlWe accept collective orders for cutting, heat treatment and various coatings up to grinding.

-

High-precision Finishing of Products with

Difficult ShapesWe mobilize techniques of craftsmanship to accommodate machining of any product shape with the required precision.

A variety of facilities such as NC lathe,

machining center,

universal grinding machine,

internal grinding machine,

surface grinding machine,

gun drill machine, etc.

in our possession.

To meet a variety of requests from customers regarding machines, jigs and tools, machining steps, we have an integrated production system from design to finished products, encompassing grinding, cutting, deep hole machining, heat treatment, plating and coating.

- Spec. meeting

- Design

- Machining review

- Material procurement

- Cutting

- Heat treatment

- Grinding

- Plating/

blackening,

etc. - Final inspection

- Shipping

Flow of integrated production (Ex.)

One of the strengths of Hikari Kikai Seisakusho is the excellent track record of our manufacturing machines, jigs and cutting tools, which other companies find difficult as well as turning, polishing and grinding of round products, which are technically challenging.

High-precision Quality and Short Delivery Time

The main reason that Hikari Kikai Seisakusho is chosen is our technology for polishing/grinding technically challenging products with high-precision finishing. We also accommodate a short delivery time for prototyping and implement thorough delivery control for small and medium lots as well. For an urgent project, we accommodate the shortest delivery time of 1 to 2 weeks from material procurement, cutting, heat treatment to grinding.

We Accommodate a Variety of Consultation for Prototyping, Development, etc.

Up to this day, we have been utilizing our technological expertise to accommodate many machining, polishing and grinding orders which other companies find difficult.

We have a rich track record not only of difficult-to-machine material but also of material which cannot be handled with cutting. If you have any machining including that for prototype development about which you do not know where to order or any project with technological challenges, please feel free to contact us.

We Deliver Microlevel Precision Machining with Consistent Quality

We accommodate flexibly not only on mid-size lots of approx. 500 pieces but also small lots starting with 1 piece.

Also, we deliver products with stable quality without precision fluctuation under a thorough quality control.

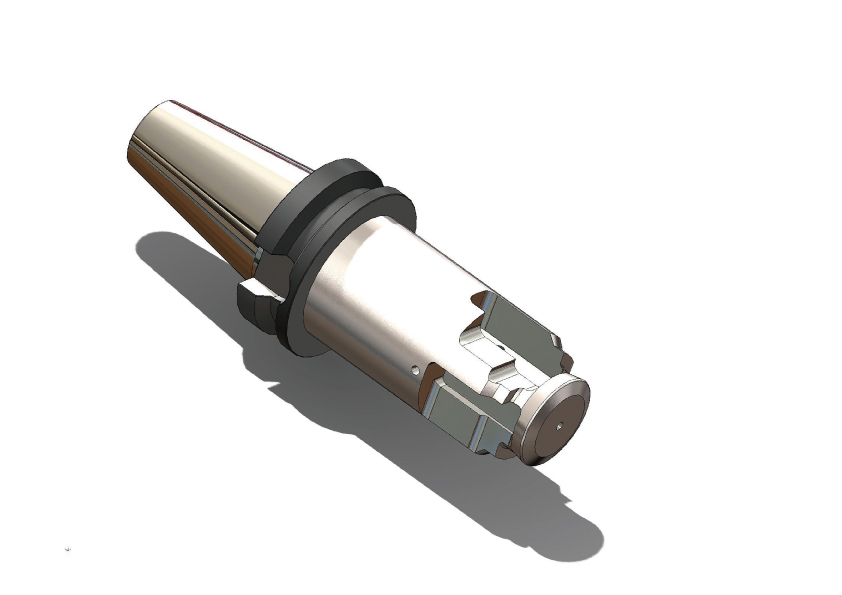

Taper Machining

For Morse taper shown in the left fig.

national taper, Brown & Sharpe taper, Jacobs taper, etc., we guarantee the taper fit ratio of 80% or above.

Scope/Description of Machining

| Material accommodated | S45C / SCM / SNCM / SUJ2 SK / SKD / SKH SUS303 / SUS304 / SUS310 / SUS316L SUS403 / SUS420J2 / SUS440C / SUS630 ※Aluminum is accommodated only for surface grinding. |

|---|---|

| Lot accommodated | From 1 piece to 500 pieces per month. For others, please contact us. |

| Size accommodated | Round: Dia.3mm to dia.300mm Square: Max. 500mm×500mm (It varies depending on the type of machining) |

We have facilities for general machining +

polishing/grinding with microlevel precision.

- Grinding facilities

-

Cylindrical grinding machine

Internal grinding machine

Surface grinding machine

- General machining facilities

-

Machining center

Combined milling machine

NC lathe

- Measuring facilities※

-

Coordinate measuring machine

Roundness measuring machine

Surface roughness measuring machine

Profile measuring machine

Helitcheck

※Measurement is conducted in a measurement room with constant temperature control.