- Home

- Hikari Values

Hikari Values

“Wow!”

This is the most delightful word for us to

receive from our customers.

We can hear it only when we get everything lined up to meet the needs and address the concerns of our customers, namely, innovative idea which positively

exceeds expectation, advanced technology and solid quality.

It is the best appraisal that

we can receive as a manufacturer.

The vision of Hikari Kikai Seisakusho is

“Creation of Wow (ingenuity) Culture”.

Let us introduce eight strengths of Hikari Kikai Seisakusho, which are the source for this “Wow!”

Eight strengths of

Hikari Kikai Seisakusho for “Wow!”

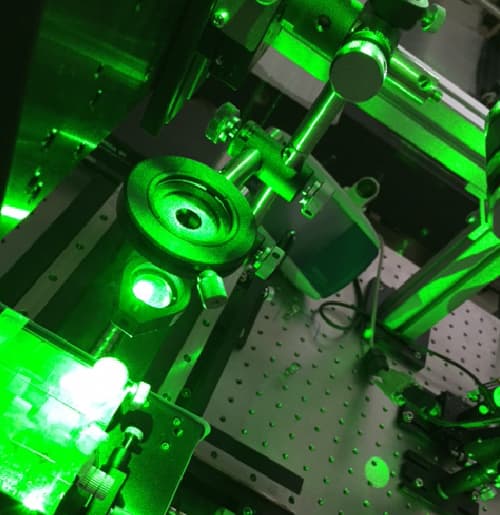

Enhancement of R&D Activities

Technological innovation is ceaselessly under way on the manufacturing floor and the grinding technology, which is essential for machining of any type of parts, is required not only to respond swiftly to any upstream change, but also to make new proposals which bring changes to end products.

Every day, across the company, we at Hikari Kikai Seisakusho, through cross-functional sharing of information and ideas, deepen our proprietary technology, conduct R&D for new technology, make prototypes for commercialization and conduct research on technology from upstream to downstream and product trends.

In 2013, we made our R&D department for laser microfabrication (micron order) independent to establish “HIKARI LASER LAB” as our first R&D base. Also, in recent years, in order to accelerate such R&D, we have been strengthening our collaboration with the R&D units of our customers and business partners as well as academia such as universities and technical colleges to promote open innovation.

Since our foundation, our R&D capability, one of our strengths, has been turning out a variety of machine tools which exceed standards for high precision, high speed, automation of complex machining, stabilization of machining of difficult-to-machine materials, etc.

Striving for Highest Standard of Quality

The products and technology we offer are required of the microlevel precision. The quality which Hikari Kikai Seisakusho is committed to is not only the precision but also the durability and machining speed which realize such precision in a consistent manner.

Our machine tool factory, a hub of manufacturing, is certified for ISO9001(Quality Management System)”, highly regarded international quality standard and implements the world-class quality management system. Also, all processes from design, procurement, inspection to delivery, all of which work in liaison with the machine tool factory, share a similarly stringent quality management standard for continuous quality improvement.

Specifically, we use high-precision coordinate measuring machines and the latest CNC multi-axis measuring machines to control every product to be shipped from Hikari Kikai Seisakusho in the micron order.

Further, we have a system in place in which the Quality Assurance Section supervises the quality management system in all the processes and ensures that the quality control is thoroughly implemented companywide.

The fact that the products of Hikari Kikai Seisakusho have been chosen to manufacture ultraprecision equipment such as airplanes and medical devices is one of the proofs of our quality.

Creation of Innovation

The history of Hikari Kikai Seisakusho, which started soon after the end of World War II, has been, in a way, the iteration of large and small innovations. We make what is not available, find technology to make up for what is lacking and teach ourselves if there is no teacher. We have been repeating this procedure on a daily basis.

Hikari Kikai Seisakusho, where such spirit has been passed down continuously, has turned out many products which rose to be the first in the industry.

Many of the inquiries we receive are challenging;” We have been turned down by another company”; “The existing equipment cannot solve it.”; “We cannot find machining methods.”

Each one of us racks our brain and comes up with ideas. Also, at other times, we as a team, combine existing technologies to create new technologies. In this way, we ensure that we never fail to present a solution for any inquiry. This stance which has never been changed since our foundation is the source of our innovation, which induces a “Wow!” from our customers.

Transmission of Techniques

The expertise and techniques about machine tools centering on grinding machines as well as cutting machines handed down through our history of 70 years are our major strengths.

The techniques, knowhow, hunches and skills which have been accumulated only through repetitive research and prototyping, learning from failures and successes and daily diligent work as professionals, are now utilized for manufacturing and have become the foundation for the state-of-the-art technology of Hikari Kikai Seisakusho. Because of such accumulation, we can accommodate a variety of challenging inquiries.

The techniques we have been preserving and carrying on are passed down from our senior to junior members even today in the “Manufacturing Training School” organized in-house.

From Mie to the Factory World

The products of Hikari Kikai Seisakusho are used for automobiles, telecommunication devices such as smartphones, airplanes, space satellites, medical devices, etc. in a variety of industries including leading makers in the world. Their production sites are located in more than 10 countries/regions including South Korea, China, Taiwan, ASEAN, India and European and American countries. Our track record of responding meticulously to innumerable specifications required by a variety of global production sites is the proof of customization capability of Hikari Kikai Seisakusho.

From Mie to plants around the world. Equipped with Japanese manufacturing spirit and global perspective, we continue to meet each customer’s unique needs in minute detail to provide products and services which enhance production technology.

Hikari’s Team Spirit

We at Hikari Kikai Seisakusho, undertake every project with the spirit of all hands on deck. This becomes one major drive for us to solve sometimes challenging issues from customers and to create high-quality and value-added products.

While each of us exerts our individuality in our position, we collaborate flexibly across departments/groups and as the “ALL HIKARI” team, we breathe life into the project. For example, the production dept. provides machining hints and comments on material for a subject workpiece. The mechanical designer collaborates with the program designer. The sales dept. sometimes suggests revision of design/production process as required with consideration given to the customer’s budget. In this manner, all members from sales, design, procurement, production, finishing, quality control and after-sales service, come up with wisdom and ideas to prepare the best strategy, realize the optimization of hardware and software and pursue the high efficiency of work and the quality management for the entire process.

We believe that the strength of the All HIKARI team is vital not only for delivering the product that meets the customer needs but also eventually for providing the merit of cost efficiency and the productivity of manufacturing floor.

Diversity

The customers of Hikari Kikai Seisakusho are companies in various industries in the world. With globalization and increased use of information, we can expect an ever-increasing diversification of customer needs and production bases. In order to continuously create innovation in this changing market environment and achieve customer satisfaction with the “Wow!” factor, we ourselves also need to understand and embrace diverse values and create the culture in which we can enjoy challenges surpassing the old framework.

For that, Hikari Kikai Seisakusho has set the human resource policy of “3G: Gender-free, Generation-free and Global)” and devoted ourselves to recruit and develop diverse human resources regardless of age, gender or nationality.

Women Empowerment

Easy-to-turn handle, switches placed collectively at hand, operational interface recognizable at a glance, safety-focused machine design. These are some of the many manufacturing examples of Hikari Kikai Seisakusho in which women’s viewpoints are utilized.

Among our activities for diversity management, what is particularly acclaimed is our promotion of women empowerment. It is said that manufacturing companies are relatively lagging behind in women empowerment. However, in our company, women account for approx. 20 to 30% of all employees, and they are also working energetically in the design and the manufacturing floor, key to manufacturing. Also, in managerial positions, women account for 20%. Both at key positions and in the front lines, our women members are performing brilliantly.

Women’s viewpoints have become the driving force for valuable proposal for customers’ manufacturing floor where aging and diversification of nationalities are under way. Also, their detailed observation capability, which further strengthens quality control and production control, has become essential for Hikari Kikai Seisakusho.

Also, in order to support women who cannot obtain employment opportunities in spite of their willingness to work due to such life events as marriage or childbirth, we have a flexible system in place accommodating each circumstance and help them visualize their career path for their empowerment.

Awards for Diversity

Our various activities for diversity have been recognized and we have been awarded and selected as follows:

- 2009

- “Encouragement Award for Companies with Men and Women Working Lively” by the Selection Committee of Mie Prefecture

- 2011

- “Equality/Work and Life Balance Promotion, Mie Labor Bureau Director Excellence Award” by the Ministry of Labor, Health and Welfare

- 2014

- “Diversity Management Selection 100” by the Ministry of Economy, Trade and Industry

“Encouragement Award of the First Empowerment Grand Prize” by the Japan Productivity Center

“50 Leading Companies for Women in APEC” by the Ministerial Meeting of APEC(5 companies selected from Japan)

- 2016

- “Vibrant HABATAKU Small and Medium Enterprises 300 (Human Resources Category)” by the Ministry of Economy, Trade and Industry/ Small and Medium Enterprise Agency