- Home

- Manufacturing of Machine Tools

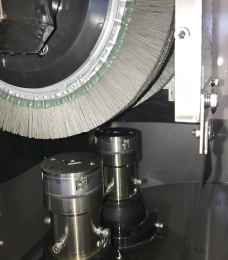

- Brush-honing machine

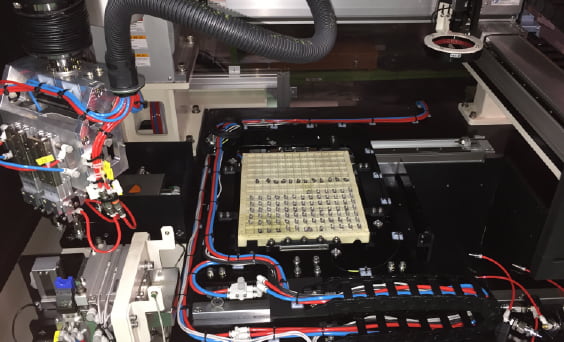

Fully unmanned operation of high-precision R honing Brush-honing machine HBR-250

Features of Machine

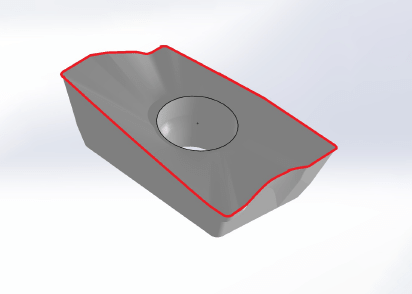

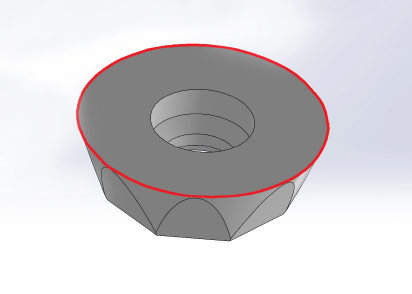

01 Microlevel control of R honing of cutting edge

R honing of insert can be conducted with microlevel precision for 2 workpieces at the same time.

Also, complex 3D-shaped inserts can be accommodated with the synchronous control software.

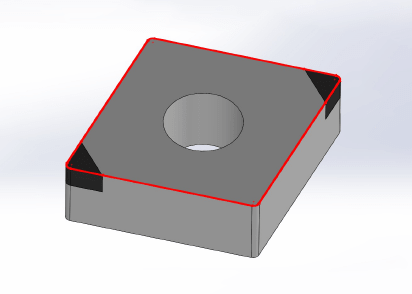

02 Honing ratio setting change is available.

The dedicated machining software allows the honing ratio for cutting edge to be changed, which is not provided by a general-purpose machine. This, in turn, allows an ideal cutting edge shape suitable for the property of workpiece to be achieved.

03 Automatic transfer of workpieces

The transfer robot and the pallet stacking device enable the fully automatic process of workpieces.

SPECIFICATIONS

| Applicable work size | Inscribed circle | 3.97mm - 16.0mm |

|---|---|---|

| Thickness | 2.38mm - 6.35mm | |

| Grinding unit | Elevation axis (Z axis) |

30mm |

| Oscillation axis (Y axis) |

0-10mm | |

| rpm | Max. 3000min-1 | |

| Grinding wheel size |

OD 250mm ID 50.8mm W 25mm T 35mm |

|

| Machine size | W1805mm × D1170mm × H2100mm (Without Loading & Un-loading unit) W2665mm × D1365mm × H2100mm (Loading & Un-loading unit, Included) |

|

| Power supply | 15KVA | |

| Control unit | FANUC 4 axis control | |

|---|---|---|

| Loading & Unloading system | YAMAHA scara robot | |

| Work unit | Work push / elevation axis (X axis) |

30mm |

| Carrier jigs (C axis) |

1~360° | |

| Dress unit | rpm | Max. 1550min-1 |

| Dressing wheel size |

OD 100mm ID 25.4mm T 20mm |

|

| Machine weight | 4000kg (Loading & Un-loading unit, Included) |

|