Hikari Kikai Seisakusho Co., Ltd. provides all that’s possible for improving your factory intelligence: Machine tools, Cutting tools, Retrofit/Overhaul, Solar Tracking Systems, etc.

| Products & Services Machine tools |

Over more than 65 years, the “Grinding Machines of Hikari” have been used on many manufacturing shop floors where high precision is required. Our technological capabilities for identifying workpiece characteristics and grinding points and realizing superior grinding performance have produced many first-of-its kind grinding machines. Also, out dedicated machines and electrolytic grinding machines for carbide tool processing have the largest market share in various categories in Japan. We customize design and manufacturing for CNC and other various grinding machines to match needs and specifications., |

| Grinding machines

(Thickness processing) |

Double-disc grinding machines (oscillating type/planetary type), Bottom grinding machines |

| Grinding machines (Tool edge processing) |

Brush-honing machines, Nose-R grinding machines, Diamond tool grinding machines |

| Other grinding machines | Chip breakers |

| Grinding machines for alloy products | Inside diameter/outside diameter lathe (vertical type/horizontal type), Oil-hole processing, Lead groove processing Cylinder forming, cutting |

| Electrolytic grinding machines | Carbide roll grinding (vertical type/horizontal type) |

| Line automation | Automatic loading/unloading system, Image processing system, Inspection equipment, Various line setup |

| Complex machines | Complex machine solution available only from a dedicated machine manufacturer |

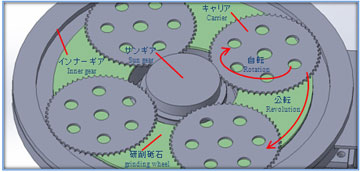

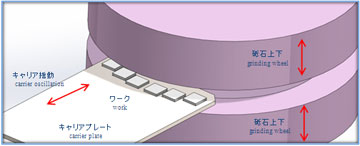

Grinding machines (thickness processing)

| CNC Double Disc Grinding Machine/ Oscillation-type | ||

| Long seller for over 25 years This double disc grinding machine was designed to grind the top and bottom faces of inserts with two numerically controlled grinding wheels. We have achieved high efficiency and good maintenance performance. |

||

|

| Bottom grinding machine | ||

| Special grinding machine with a solid track record. This is a vertical surface grinding machine which processes only the bottom face of workpieces. It can process, without using magnet, workpieces such as the bottom face of carbide inserts called wave mill or one face (top face) of workpieces with a three-dimensional complex shape, which an ordinary surface grinding machine cannot process. |

||

|

Grinding machines(Tool edge processing)

| Brush-honing machines |

| High-quality deburring with diamond brush This is a special machine for radius honing of throwaway tips with the micron-level precision. It can accommodate both the dry type and the wet type. Also, the brush shape can be a peripheral type or a cup type. |

|

| Nose-R Grinding machines |

| High precision grinding machine with superior operability provided by the CCD camera This is a precision grinding machine for grinding the edge of a throwaway tip or the like into a radius shape. The shape of a tool edge, which cannot be checked with the human eye, is checked with the high resolution image of CCD camera (projector) during work, which allows high precision processing. |

|

| Diamond tool grinding machines | ||||

| Absolute confidence in rigidity This is a grinding machine with a diamond tool, which is most suitable for grinding PCD, CBN, carbide and ceramic tools. The grinding wheel head moves back and forth to make cutting. Exceptional operability ・The superior operability is provided by the CCD camera which follows the motion of the work head. ・The shape of the arc (nose R) of a workpiece during work can be clearly checked with the high resolution image, which allows the processing of the minimum of 0.05 R. ・User friendliness has been pursued from the viewpoint of our female employees. |

||||

|

||||

| Chip breaker |

| This is a machine for processing the chip breaker for insert chip. |

Grinding machines for alloy products

| Vertical alloy lathe |

| Precision grinding even for difficult-to-process material This is a dedicated machine for grinding the inner/outer periphery of the intermediate sintered material of cemented carbide/ceramic with numerical control. |

|

| NC alloy hole processing machine |

| Reliable deep hole processing machine for alloy bars This is a dedicated NC machine for drilling deep holes or branch holes in alloy bars. |

|

| NC alloy cylindrical grinding machine |

| Better precision for carbide forming processing This is a grinding machine in which the outer periphery of intermediate sintered material of carbide is formed with numerical control. |

|

| NC alloy lead forming machine |

| 4-axis control for speedy lead groove forming This is a dedicated machine with 4-axis control for forming lead grooves on the outer periphery of alloy bars. |

|

Electrolytic grinding machines

| Horizontal electrolytic grinding machine |

| For processing carbide rolls, guide rolls, etc. This is a dedicated grinding machine for processing the outer periphery and grooves of carbide rolls, etc. by using electrolytic grinding and mechanical grinding. |

|

| Vertical electrolytic grinding machine |

| Combinational technology of electrolytic grinding and mechanical grinding This is a dedicated CNC machine in which electrolytic grinding is used to process the outer periphery and multiple grooves of a carbide roll, etc. with high efficiency, and then, automatically switched to mechanical grinding, which conducts finishing grinding. |

| Line automation | ||

| Realization of automatic/unmanned operation of multiple processes with ease. The image processing unit equipped with a CCD camera and the transfer equipment consisting of a robot and a palletizer are most suitable for the automatic/unmanned operation of pallet repacking or inspection equipment. The position and orientation of a workpiece is checked and even the positioning during machining is conducted automatically. The input and operation of setting items can be done on the screen easily just like Word or Excel. Therefore, in the case of multiple processes of small-lot products, if setting is conducted in advance, unmanned operation without stopping the machine is possible. |

||

|

| Support for complex machines, distinctive of a dedicated machine maker We offer proposals for and manufacturing of complex machines which combine multiple grinding machines and transfer equipment to match each customer’s needs. Many advantages from complex machines Complex machines in which various grinding machines are combined and transfer is conducted by conveyor/robot to load/unload workpieces have many advantages. Combining multiple processes to make a line not only enhances production efficiency but also reduces space and equipment introduction cost. Being a dedicated machine maker, we can offer an optimum design for an entire system which can make best use of the features of each machine/process and gives consideration to space saving. We can also support the solution for multiple machine models. |

| Case: Complex compound underside grinding machine and brush-honing machine |

| This is a compound machine in which workpieces are transferred between an underside grinding machine and a brush-honing machine by a robot. |  |

バナースペース

Attention!

Our new Heriostas for CSP has been just introduced!

Hikari Kikai Seisakusho Co., Ltd.

8-1 Isshinden Nakano

Tsu-city, Mie 514−0112 Japan

Tel:+81-59-227-5511

Fax:+81-59-227-5514

Mail: info@hikarikikai.co.jp

8-1 Isshinden Nakano

Tsu-city, Mie 514−0112 Japan

Tel:+81-59-227-5511

Fax:+81-59-227-5514

Mail: info@hikarikikai.co.jp